There’s a big difference between drawing up blueprints and actually building a house.

You could probably read that on a deep metaphorical level and apply it to all aspects of life, but in this particular instance I’m being quite literal.

But if Tennessee’s Branch Technology gets their way, soon constructing a house could be just as easy as hitting “print.”

Based in Chattanooga, Branch Technology is a new technology start-up founded by Platt Boyd and Christopher Weller, a pair of architects with a shared interest in robotics and 3D printing. They’ve also been next-door neighbors for more than a decade.

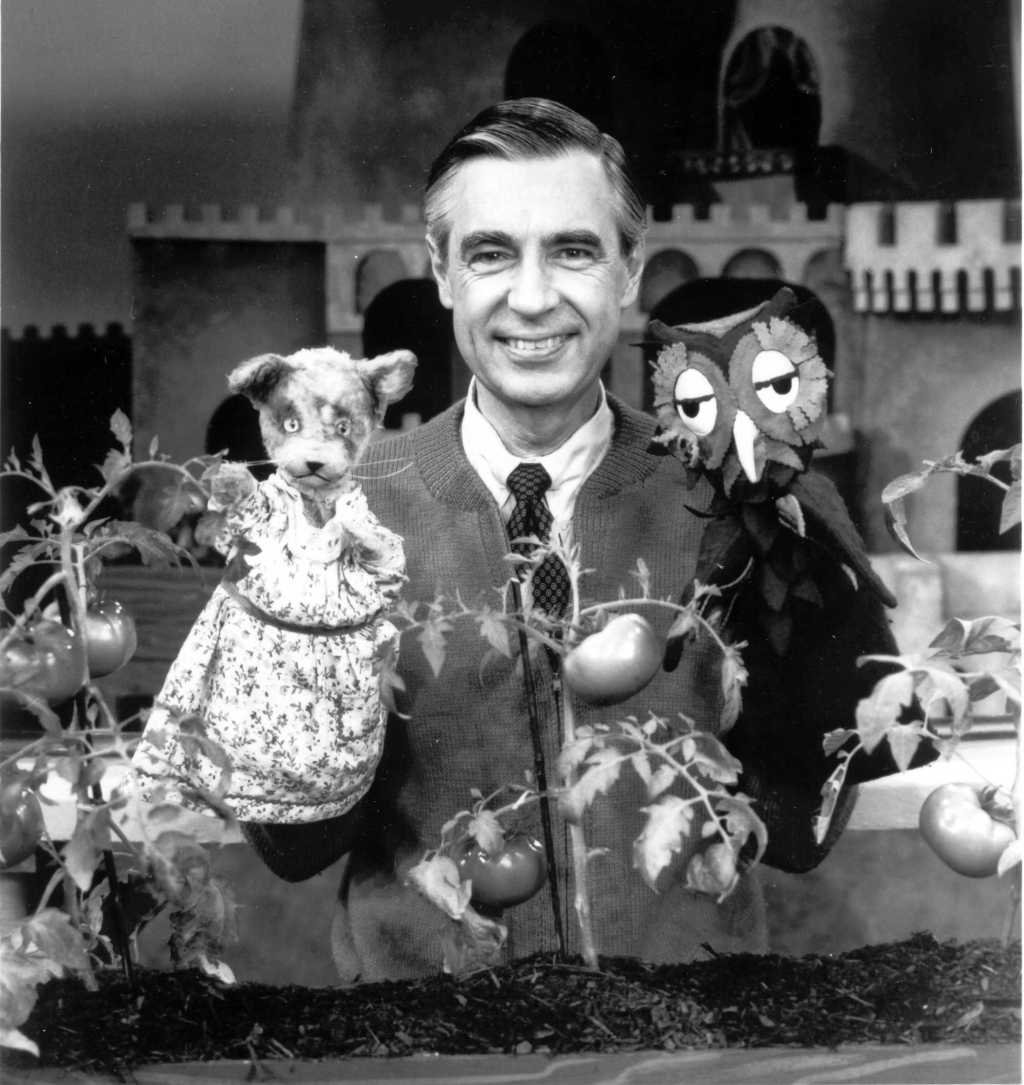

Branch Technology co-founders Platt Boyd and Christopher Weller. Photo courtesy of Branch Technology.

Branch Technology has indeed built the world’s largest freeform 3D printer — and they’re using it to print new walls for houses.

In the same way that standard printers release tiny blasts of ink along a 2-dimensional grid, traditional 3D printers (well, “traditional”) use a combination of bonding agents and a material such as plastic to build something layer-by-layer within a confined 3-dimensional matrix.

But Branch Technology has found a way to free the 3D printing process from those physical constraints by converting an old automobile manufacturing robot.

“When geometry is not an issue, you can do almost anything. If an architect can send us an original design file we can fabricate that,” Branch founder and CEO Platt Boyd told Gizmodo. Imagination is actually the limit. (OK, there are probably a few limits — stupid gravity always wins.)

The machine can print dense, lightweight scaffolding in any shape or size.

Thanks to their patented Cellular Fabrication process (or “C-Fab”), Branch has found a way to replicate the optimized geometries of complex cellular structures such as trees or bones.

“It all comes back to how nature builds things,” Branch’s Shawn Thorne told Upworthy. “We’re really asking the fundamental question of how little we can 3D-print, instead of ‘3D printing is cool and how much can we do.’”

GIF via Branch Technology.

To achieve this, Branch 3D-prints an internal structural scaffolding for their walls, then fills in the rest of the space with spray foam, concrete, or other traditional construction materials. This allows them to cut down on time and costs without sacrificing quality, aesthetic, or structural integrity.

It also means that the structures are completely customizable, and can be combined with other construction materials and methods.

Image courtesy of Branch Technology.

These 3D-printed walls can be easily integrated into current construction standards, kind of like LEGO for grown-ups.

Don’t worry about the robots coming to steal our jobs — Branch Technology’s process still requires human beings to assemble the actual pieces and turn them into a house. Fortunately, their walls comply with all the best practices of traditional construction, which means you can use as many or as few 3D-printed walls as you’d like, and there won’t be any learning curve for contractors.

Maybe you want to add a new wall to section off an office space from your living room, or you want to tear down that wall between the kitchen and the dining room. Either way, Branch’s 3D-printed walls could make the interior decorating process a lot less complicated.

Traditional construction materials are used to make the gaps between each wall piece disappear, just like you would with Sheetrock panels. Branch’s proprietary algorithm allows the individual wall segments to mesh seamlessly together, and you can even break the walls down and transport them in smaller, manageable pieces to be assembled later. The individual panels can then be replaced without a problem if something breaks or you decide to redesign.

The 3D-printed walls are also LEED certified (Leadership in Energy & Environmental Design), which means they’re sustainable and environmentally friendly.

And that’s just really cool.

Companies in Amsterdam and China have also made significant strides towards the creation of fully 3D-printed houses.

Engineers in Amsterdam have previously tried to 3D-print houses made from plastic and 3D-print bridges in mid-air. While these experiments were both fully automated, they also took a while (like watching the incremental progress of a brand-new skyscraper being built, except worse — we’re talking two years to build a 24-foot bridge). In their defense, they were also intended more as experiments than practical applications of the technology.

The Shanghai-based WinSun company was also able to 3D-print 10 houses in just one day. (Branch predicts that they can print only 20 houses a year at their current facilities.) WinSun’s 3D-printed houses also require some manual assembly, and the fact that they each cost less than $5,000 to make is somewhat offset by the fact that, well, they’re kind of hideous industrial eyesores.

A 3D-printed house that is also a hideous industrial eyesore. Photo by ChinaFotoPress/ChinaFotoPress via Getty Images.

While we’re still a ways away from miraculously printing out mansions en masse, it’s nice to know that we’re at least on the right path.

Sure, it might be another several years before we can all 3D-print our dream homes, but who knows? Maybe keeping all those irrationally elaborate tree house designs you drew as a kid will finally pay off…

Photo by Thomas Pusch.